What we do

CRC Evans delivers expert welding, coating and project services as part of a wider portfolio that also includes technologies and integrated solutions. We partner with customers anywhere across the globe on their fabrication and infrastructure projects.

Extending our capability

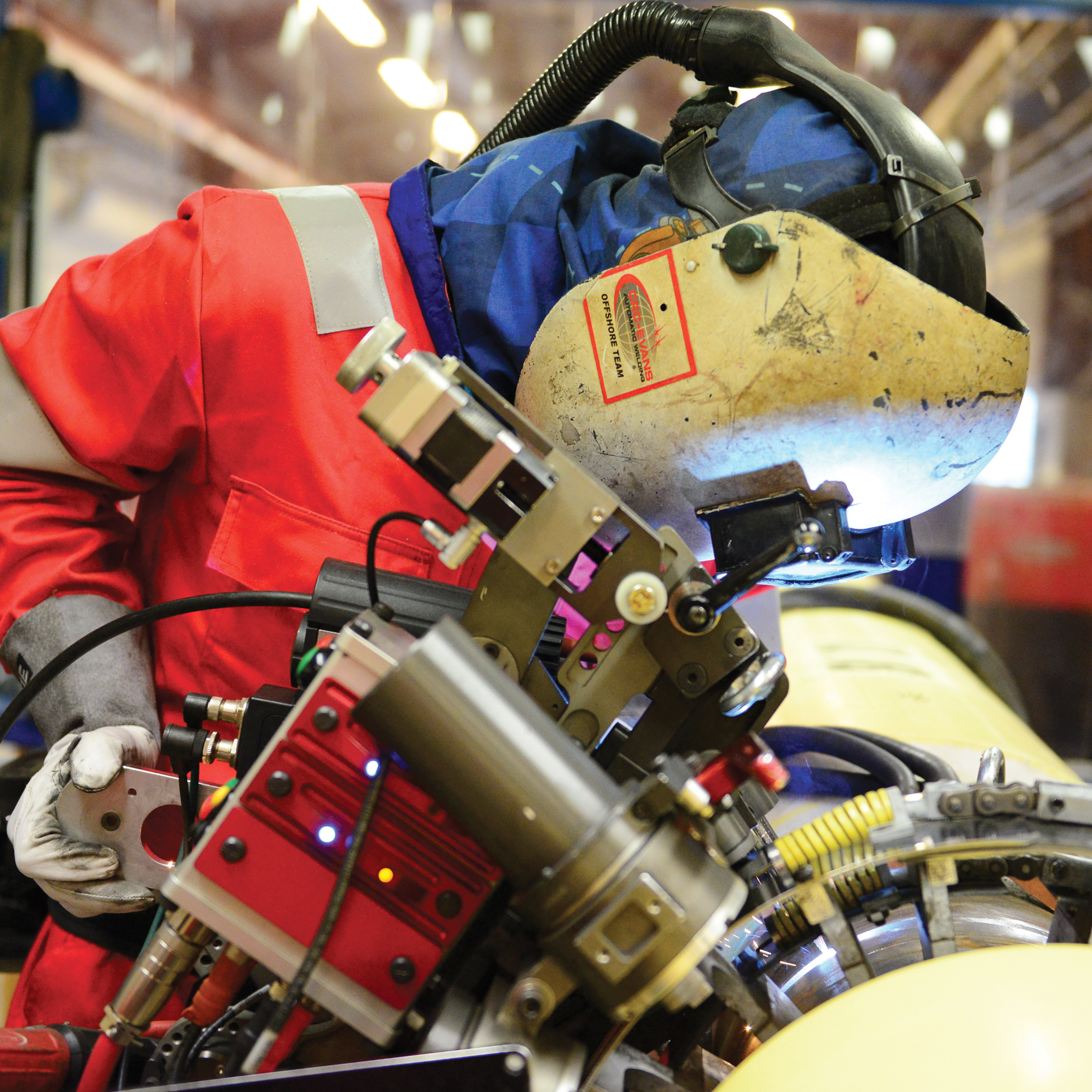

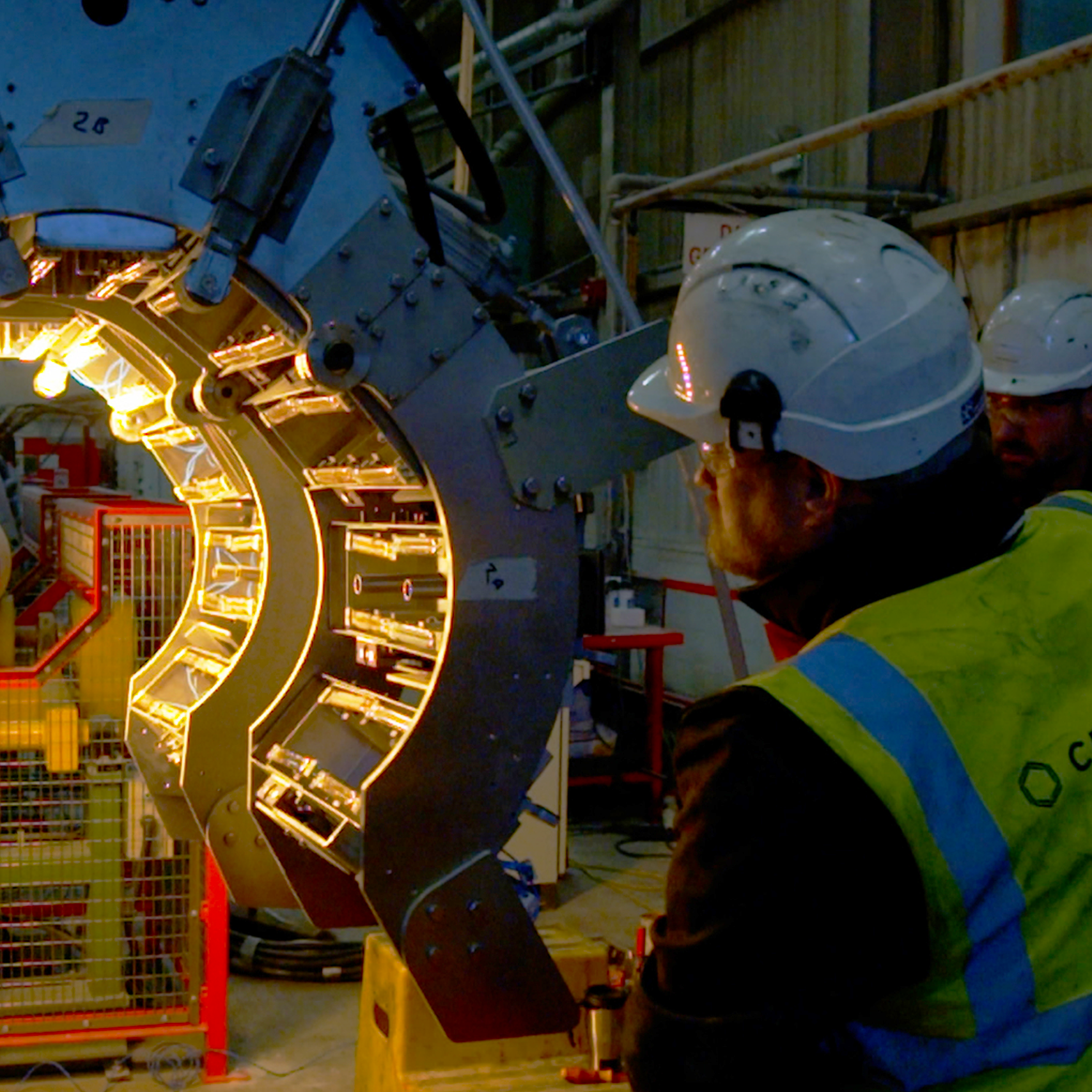

CRC Evans is the largest provider of specialised services for projects requiring automated welding and field joint coating solutions. Our large fleet of equipment and experienced team of technicians and engineers provides the resources and sector experience to support our global customer base.

Our safety mindset is the result of a high-performance approach where every individual is encouraged to reach their full potential through application of effort and a commitment to quality.

Strategic acquisition has allowed us to significantly extend our capabilities to ensure that our high-quality welding and coating services are available to customers across multiple global locations. Our focus on organic growth will drive improvement across our business, as we develop our people, our processes and our technologies to meet the challenges of tomorrow.

At the forefront of innovation

The experience and knowledge of our people is driving the development of new technologies and solutions that will provide greater efficiencies for our customers. With a dedicated R&D team that is committed to delivering innovative solutions, we can harness the unique methods and skills that are needed in our sector through technology, helping to improve efficiencies across our customers’ projects.

Our welding and coating specialists will support you at every stage, from project planning to delivery.